In the past decade, advances in synthetic biology paved the way toward sustainable synthesis of complex natural products, such as terpenoids and alkaloids. The baking yeast Saccharomyces cerevisiae has been widely used in the food industry and has become one of the main platforms for building cell factories due to its robustness, convenient cellular engineering and reliable safety. Although enzyme engineering and pathway engineering have been widely used to improve the performance of yeast cell factories, the role of cofactors in microbial production was largely ignored.

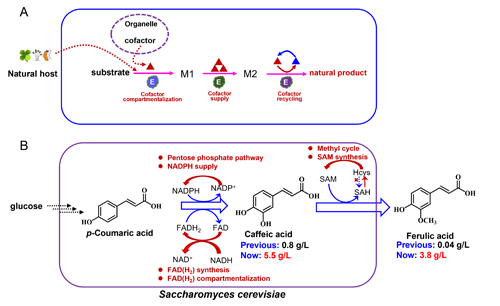

We, in collaboration with Prof. Zhang Lei from Naval Medical University, developed efficient cofactor engineering strategies to derive phenolic acid biosynthesis in yeast (Fig. 1). Engineering supply, re-localization and recycling of cofactor NADPH, FAD(H2), and SAM enabled high level production of caffeic acid (5.5 g/L) and ferulic acid (3.8 g/L). This work reveals the regulation of different cofactors in yeast, especially the distribution of cofactors between different organelles in cells, and provides theoretical guidance for cofactor engineering. It will also provide sufficient precursors for the efficient synthesis of complex active natural products (lignans and polyphenolic acids, etc.).

This work, titled “Engineering cofactor supply and recycling to drive phenolic acid biosynthesis in yeast”, was published in Nature Chemical Biology. This work was funded by the National Key Research and Development Program of China, National Natural Science Foundation of China, LiaoNing Revitalization Talents Program and Innovation grant from DICP. (Text and image by Ruibing Chen)

Fig. 1. Cofactor engineering ensures efficient synthesis of natural products in yeast factories.

中文版