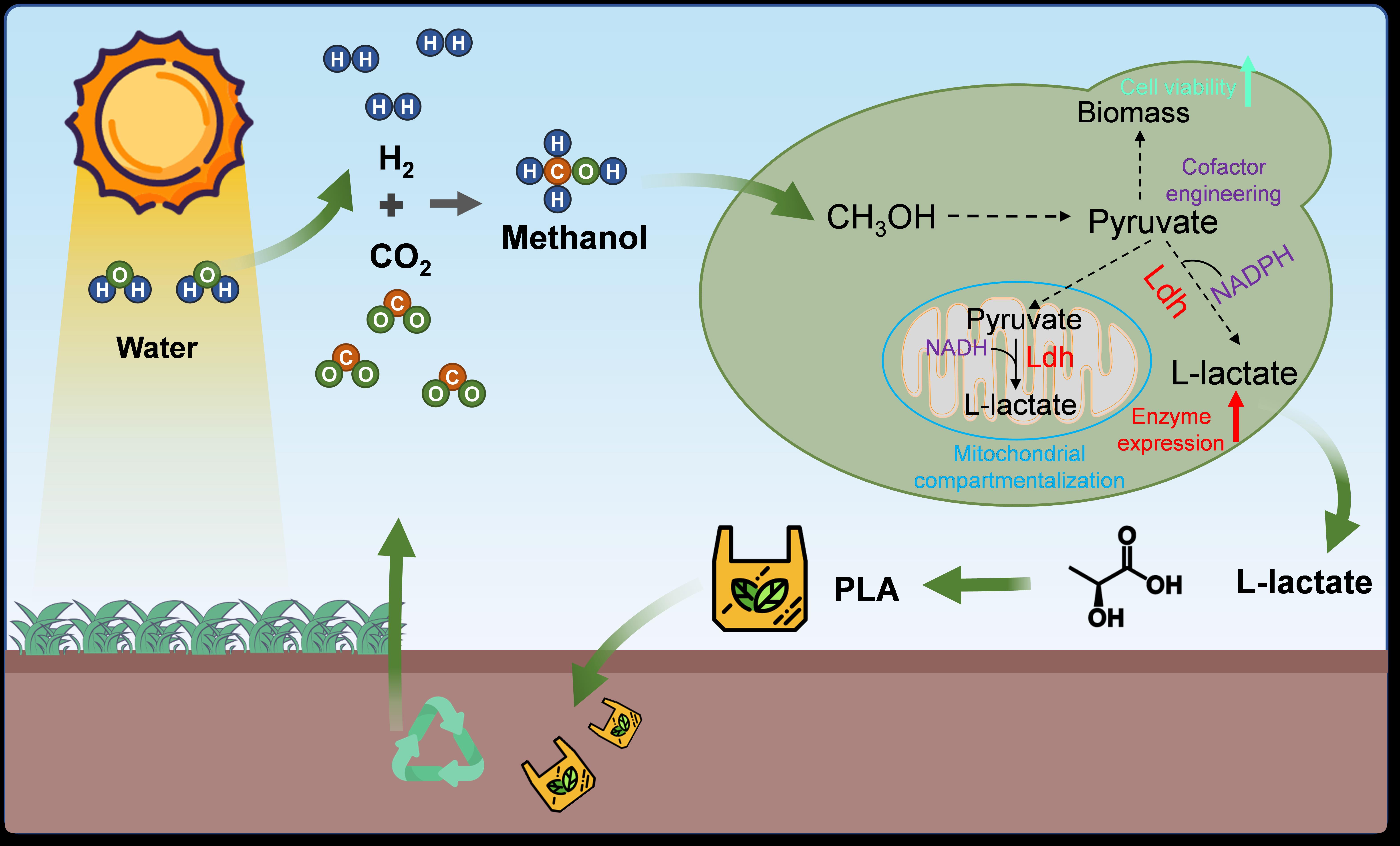

Methanol is an attractive feedstock for bio-manufacturing, and converting it into lactate, a monomer for biodegradable plastic, offers a promising strategy for addressing the challenge of white pollution. However, engineering microbes to produce lactate from methanol remains difficult due to methanol toxicity and strong competition between product synthesis and cell growth.

Our group, in collaboration with Prof. FEI Qiang from Xi’an Jiaotong University, has developed a yeast cell factory to produce L-lactate from sole methanol. The team further conducted techno-economic analysis (TEA) and life cycle assessment (LCA) to evaluate the commercial potential and environmental impacts of this bioprocess.

To achieve efficient lactate production, researchers extensively rewired the metabolism of the yeast Ogataea polymorpha for overproduction of L-lactate from methanol and discovered a distinct cofactor distribution pattern in methanol metabolism. Based on this cofactor regulation mechanism, they developed cofactor engineering and mitochondrial compartmentalization strategies, which substantially enhanced L-lactate biosynthesis.

Moreover, TEA and LCA demonstrated the economic and environmental value of producing CO2-derived L-lactate by coupling chemical and biological catalysis. This study lays the foundation for the carbon-neutral production of the biodegradable plastic polylactic acid from CO2.

"Our work not only paves the way for engineering methanol metabolism to produce lactate," said Prof. ZHOU, "but also presents a broader vision for a circular economy by establishing a direct link between biodegradable plastics and carbon neutrality." (Text and image by Wei Yu)

Link: https://doi.org/10.1038/s41467-025-65793-x

中文版