Medium- and short-chain fatty acids (C8–C14) are widely used in food, pharmaceuticals, lubricants, and surfactants. Currently, these compounds are mainly extracted from coconut and palm oils, a process associated with significant land use and ecological concerns.

Developing sustainable microbial alternatives, especially methods for producing fatty acids with high purity and precise chain-length control, is a major goal in synthetic biology and metabolic engineering. However, traditional microbial approaches often suffer from broad product distributions with limited specificity, hindering industrial applications.

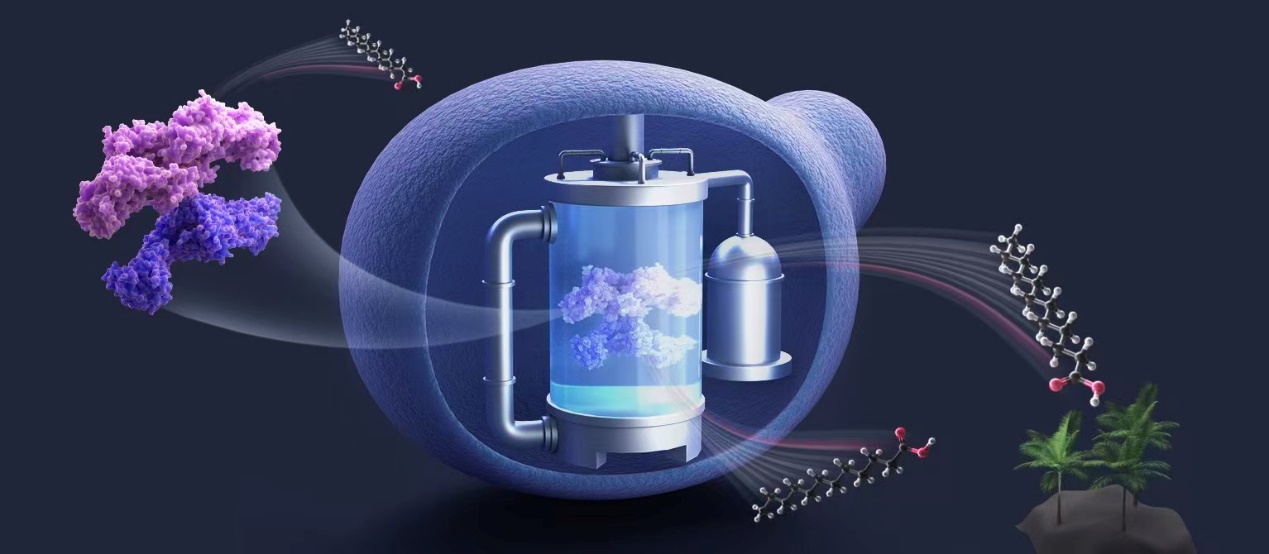

In a recent study published in Nature Chemical Biology, a collaborative team led by Prof. Martin Grininger from Goethe University Frankfurt and our group developed a modular and programmable fatty acid synthesis platform that enables high specificity production of medium-chain fatty acids in yeast.

Prof. Grininger’s team engineered a metazoan fatty acid synthase (mFAS) through targeted mutations, modulating the activity of its ketosynthase (KS) and thioesterase (TesA) domains to precisely control fatty acid chain length.

Our group constructed an efficient yeast cell factory by using the industrial yeast Ogataea polymorpha. The optimized mFAS/TesA system was integrated and co-expressed alongside engineered fatty acid metabolism. These modifications blocked the complete degradation of long-chain fatty acids and redirected metabolic flux toward medium-chain products.

As a result, the engineered strain O. polymorpha XMCFA69 achieved a medium-chain fatty acid titer of 708.6 mg/L, with lauric acid (C12) accounting for 48% of the total products - comparable to its abundance in coconut and palm kernel oils.

“We have established a programmable, chain-length-controllable platform through synergistic enzyme and metabolic engineering,” said Prof. ZHOU. “This demonstrates the potential of synthetic biology for sustainable chemical manufacturing and offers a viable alternative to plant-based fatty acid extraction.”

The study was supported by the German Research Foundation, National Natural Science Foundation of China, the Sino-German collaboration project, and the Unilever R&D Fund. (Text and image by Xiaoxin Zhai)

Link:http://english.dicp.cas.cn/news/rn/202303/t20230327_328739.html

中文版